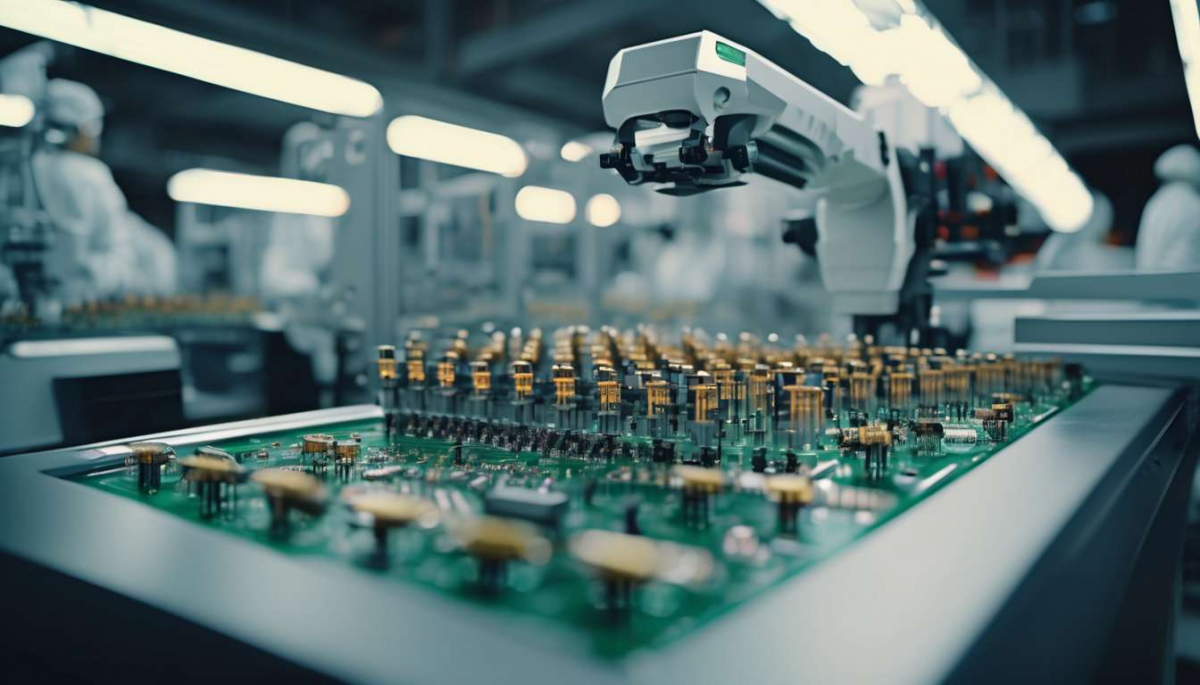

Just a few years ago, in a bustling electronics manufacturing facility in Shenzhen, a potential production catastrophe unfolded. The assembly line, responsible for churning out thousands of units daily, came to a sudden halt. A small component, crucial in the final product, was found to be defective, threatening significant delays and financial implications.

This scenario, although challenging, highlights several key aspects of electronics manufacturing:

- The intricate nature of the production process.

- The importance of meticulous quality control.

- The necessity for supply chain precision.

In the increasingly competitive global market, manufacturers face mounting pressure to:

- Optimize processes.

- Reduce lead times.

- Maintain impeccable standards.

Technological advancements continue to reshape the landscape, while regulatory demands add layers of complexity that must be navigated meticulously.

The sector’s dynamism offers significant opportunities for innovation, yet presents challenges that require strategic foresight and adaptability.

Understanding the multifaceted dynamics within electronics manufacturing is essential for stakeholders aiming to excel within this critical industry.

Among the multitude of solutions available to navigate these complexities, Atlas Copco‘s innovative technologies play a pivotal role in enhancing efficiency and reliability in electronics manufacturing.

Production Process Complexity

The electronics manufacturing industry involves a highly intricate production process, requiring meticulous coordination of various components and technologies. Achieving production efficiency is paramount, as it ensures the seamless integration of these elements.

Efficient production processes rely on advanced planning and execution strategies, which:

- Optimize the use of resources

- Minimize waste

In this complex environment, quality assurance plays a critical role in maintaining high standards throughout the manufacturing stages. By implementing stringent quality control measures, manufacturers can:

- Detect potential issues early in the process

- Address these issues promptly

- Enhance the overall reliability of electronic products

Supply chain management forms a crucial aspect of the production process complexity. Effective supply chain management ensures:

- Timely delivery of components

- Accurate delivery of components

- Maintenance of production schedules

- Reduction of lead times

The careful orchestration of these elements fosters a sense of belonging among industry participants, as they work collaboratively to meet the growing demands for innovative and reliable electronic devices.

Quality Control Imperatives

Robust quality control is essential in electronics manufacturing to ensure products meet stringent industry standards and customer expectations. Implementing comprehensive quality assurance protocols enhances production efficiency by minimizing defects and reducing rework, thus optimizing resource utilization.

Precision in manufacturing processes not only fortifies the integrity of the final products but also instills confidence in stakeholders, fostering a sense of unity and trust within the industry.

Advanced quality control systems, incorporating the latest technological advancements, serve as a cornerstone for maintaining consistency and reliability. These systems enable early detection of potential issues, allowing for timely interventions that prevent disruptions in the production line. Additionally, effective quality assurance practices contribute to streamlined supply chain management by ensuring components and materials adhere to required specifications, thereby preventing bottlenecks and delays.

The integration of robust quality control measures is not merely a procedural necessity but a strategic imperative. This commitment to excellence aligns with the collective goals of the electronics manufacturing community, promoting sustained growth and innovation.

Supply Chain Precision

A meticulously coordinated supply chain ensures timely delivery of components, maintaining the seamless flow of materials essential for uninterrupted electronics manufacturing.

Effective supply chain management plays a pivotal role in:

- Enhancing production efficiency

- Ensuring high standards of quality assurance are consistently met

By precisely synchronizing the various stages of procurement, storage, and distribution, electronics manufacturers can:

- Minimize delays

- Reduce potential disruptions

A strong focus on supply chain precision allows for:

- Identification and mitigation of risks that could impede production processes

This attention to detail promotes a collaborative environment where stakeholders, including:

- Suppliers

- Manufacturers

- Logistics providers

work synergistically to achieve common goals.

The implementation of advanced technologies, such as:

- Real-time tracking

- Data analytics

further refines these processes, providing insights that support informed decision-making.

In an industry where precision and reliability are paramount, maintaining a well-organized supply chain fosters trust and strengthens relationships within the electronics manufacturing community, promoting a sense of belonging and shared success.

Process Optimization Strategies

Implementing strategic process optimization techniques can dramatically enhance the overall efficiency and output of electronics manufacturing operations.

Key Strategies include:

- Integration of Advanced Technologies:

- Automation and data analytics streamline various manufacturing processes.

- These methodologies reduce waste and minimize errors, leading to substantial cost savings and increased throughput.

Quality Assurance plays a pivotal role in maintaining high standards, ensuring that products consistently meet specifications and customer expectations.

Process Optimization in Supply Chain Management:

-

Synchronized operations are crucial for efficiency.

-

Implementing just-in-time inventory systems and fostering strong supplier relationships ensures a steady flow of materials, preventing bottlenecks and delays.

This cohesive approach enhances reliability and responsiveness, ultimately contributing to a competitive advantage in the market.

Conclusion:

Fostering a culture of continuous improvement and innovation within electronics manufacturing operations is essential. Through the adoption of these optimization strategies, organizations can achieve sustainable growth and maintain their position at the forefront of the industry.

Lead Time Reduction Tactics

Effectively reducing lead times in electronics manufacturing requires a strategic focus on streamlining processes and enhancing coordination across various production stages.

Implementing a robust supply chain management system is crucial to achieving swift and responsive operations. This involves:

- Establishing reliable partnerships with suppliers to ensure timely delivery of components

- Reducing delays in the production cycle

Adopting advanced production efficiency techniques, such as lean manufacturing, can:

- Minimize waste

- Enhance throughput

Quality assurance remains paramount, as rapid production must not compromise product standards. Strategies include:

- Employing real-time monitoring tools

- Utilizing automated inspection systems to detect defects early

These strategies ensure that quality standards are maintained without slowing down production. A synchronized approach between production and quality teams fosters:

- A culture of continuous improvement

- Mutual accountability

Integrating technology such as IoT and data analytics can further refine processes by:

- Providing insights into bottlenecks

- Enabling predictive maintenance

This integration not only accelerates lead times but also strengthens the overall efficiency and reliability of the manufacturing process.

Standards Maintenance Practices

Maintaining rigorous standards in electronics manufacturing demands continuous evaluation and updating of processes to ensure compliance and optimal performance. This practice is pivotal in achieving production efficiency as it involves a systematic approach to:

- Identifying inefficiencies within the manufacturing cycle.

- Rectifying these inefficiencies to enhance throughput.

- Reducing waste to align with quality assurance protocols that foster product reliability and safety.

Incorporating robust standards maintenance practices into supply chain management further strengthens the manufacturing ecosystem. A well-maintained supply chain ensures that:

- Materials and components meet specified quality benchmarks.

- Disruptions are minimized.

- Seamless operations are facilitated.

This proactive approach guarantees the integrity of the final product and cultivates trust among stakeholders, including suppliers and customers, thereby fostering a sense of community within the industry.

Through diligent standards maintenance, manufacturers can achieve a harmonious balance between innovation and reliability, ensuring that all members of the electronics manufacturing community are equipped to meet evolving market demands with confidence.